Fabrics, Quality, 4 point sytem

- Fabric inspection method or preparation

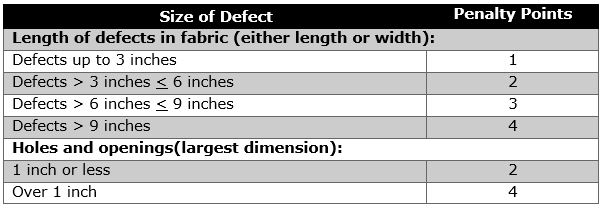

- Criteria of giving penalty points based on defects and defect length.

- Calculation method of total penalty points for total defects found in a fabric roll

- A Check sheet or format for recording data

- Knowledge of different types of defects (how a defect looks and its appearance)

Inspection Machine:

- Fabric inspection is usually done on fabric inspection machineries.

- These machineries are designed so that rolls of fabric can be mounted behind the inspection table under adequate light and re-rolled as they leave the table.

- Inspection machineries are either power driver or the inspector pulls the fabric over the inspection table.

- Some machinery is equipped to measure the length of each roll of fabric (meter/yard).

4-Point Inspection System:

Inspection Procedure:

Four-Point System, a standard established under ASTM D5430 - 07(2011), is a standardized Test Methods for fabric Visually Inspecting and Grading. Four-Point System is widest acceptance in fabric inspection due to its practical, impartial, and worldwide recognized. The four-point system derives its name from the basic grading rule that a maximum of four penalty points can be assessed for any single defect and that no linear meter can be assigned more than four points regardless of the number of defects within that piece.

Inspection Procedure:

- Receive approval colour and quality swatches

- Check lot size, lot number, roll number etc.

- Randomly draw 10% of the lot or as per AQL chart.

- Delivery of less than 1,000 yds-100% inspection

- Delivery of 1,000yds to 10,000 yds. to inspect at list 1,000 yds.

- Delivery of more than 10,000 yds. inspection 10 of the lot.

Criteria for Giving Penalty Points:

In the following table the penalty evaluation points has been given for different length of fabric defect and dimension of holes.

In the following table the penalty evaluation points has been given for different length of fabric defect and dimension of holes.

Acceptable Penalty Points: If no specified standard provided for knit fabric, the average point Value per shipment not exceed 28 points per 100SQ. Yard individual rolls exceeding 28 point shall be rejected.

Defects Condition:

- No more than 4 points will be penalized within one yard.

- Severe defects are assigned the max 4 point for each yard.

- Any hole less than 1 inch 2-points, over 1 inch 4 points and any running defect will be penalized 4 point.

- Whole roll running defect or continuous defects more than 10 yds will be reject per roll.

[Note] : If this article is helpful to you, please comment us and share it to others

Post A Comment:

0 comments so far,add yours

Post a Comment